Quantum Manufacturing: Building the Future of Production with SpinQ

2025.08.09 · Blog Quantum Manufacturingquantum computingQuantum computing

As quantum technologies transition from laboratory experiments to industrial systems, Quantum Manufacturing is emerging as a key domain. It enables scalable hardware production and quantum-enhanced industrial workflows. SpinQ is advancing this frontier through integrated device design, accessible desktop quantum systems, and partnerships that help bring quantum manufacturing to practical application.

What Is Quantum Manufacturing?

Quantum Manufacturing encompasses two intertwined dimensions:

-

Hardware Fabrication of Quantum Devices Involves scalable production of quantum chips and photonic circuits using semiconductor-grade processes, enabling consistent yields and industrial-volume manufacture.

-

Quantum-Enhanced Manufacturing Processes Combines quantum computing and AI-driven models to optimize production scheduling, supply chains, predictive maintenance, and materials discovery.

Scaling Quantum Hardware

Recent breakthroughs illustrate how quantum components are becoming industrially manufacturable:

-

A "quantum light factory" was developed using standard 45 nm CMOS processes, integrating photonic resonators, control electronics, and on-chip self-stabilization—all within a 1 mm² silicon die. This approach shows that quantum hardware can leverage existing semiconductor infrastructure for scale Tom's Hardware.

-

PsiQuantum announced mass production of its Omega photonic quantum chip at semiconductor-grade volume with foundry yields comparable to classical chips. These milestone findings suggest quantum hardware is moving toward large-scale, commercial viability Reuters.

These developments illustrate that quantum devices can be manufactured with repeatability, robustness, and compatibility with semiconductor supply chains.

Enhancing Manufacturing with Quantum Optimization

Quantum computing is already transforming industrial workflows across multiple areas:

-

Supply Chain & Route Optimization: Companies like Volkswagen and DHL are exploring quantum algorithms to optimize vehicle routing, logistics scheduling, and route planning—yielding measurable gains in fuel savings, delivery times, and efficiency TechTargetaxidio.com+2EE Times+2.

-

Inventory & Production Scheduling: Quantum-enhanced models are being applied to complex production planning, batch scheduling, and resource allocation to help minimize costs and meet demand more flexibly postquantum.com.

-

Predictive Maintenance: Quantum machine learning techniques can analyze sensor data to anticipate equipment failures and optimally allocate maintenance resources before faults occur ey.com.

-

Assembly Line Optimization: A case study using quantum annealing showed improved robotic production-line balancing for scalable customization workflows, reducing inefficiencies and enhancing productivity arxiv.org.

These applications underscore quantum computing’s ability to navigate high-dimensional optimization problems that once overwhelmed classical systems.

Market Momentum & Industry Outlook

-

McKinsey estimates that quantum computing revenue may grow from $4 billion in 2024 up to $72 billion by 2035, with manufacturing and logistics among the earliest adopters axidio.com+3postquantum.com+3EE Times+3mckinsey.com.

-

Analysts project that applying quantum AI within manufacturing and logistics could reduce inventory levels, improve throughput, and accelerate scheduling—providing direct cost savings and operational gains EE Timespostquantum.comieia.ristek.or.id.

Such market trajectory supports deploying quantum manufacturing tools into industrial pilot phases today.

SpinQ’s Role in the Quantum Manufacturing Ecosystem

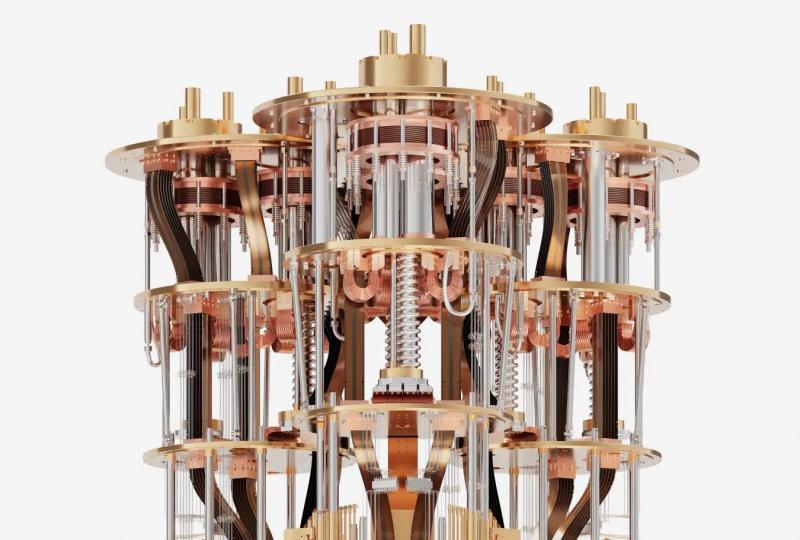

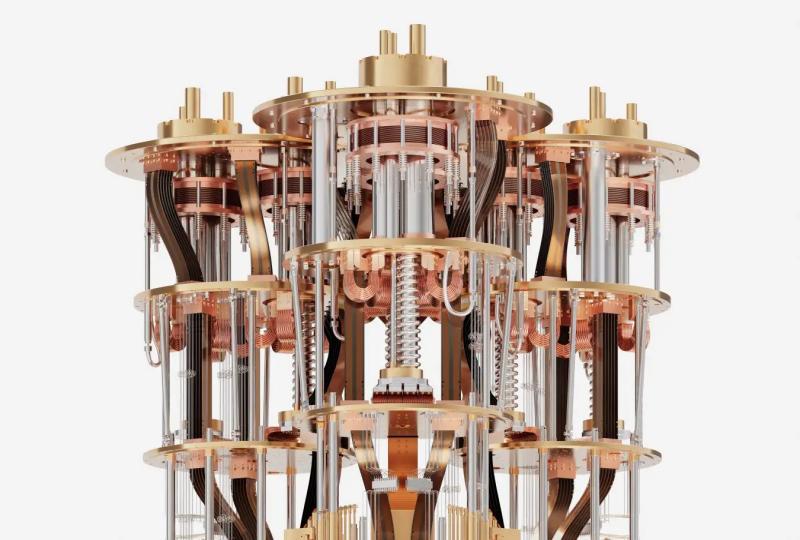

Compact Hardware for Democratized Access

SpinQ’s portable NMR-based hardware, like Gemini and Triangulum, offers reproducible, desktop-scale quantum systems that are easy to deploy and ideal for R&D, education, and pilot projects.

Scalable Control Infrastructure

SpinQ’s proprietary control electronics and firmware architecture are modular and upgradeable—enabling calibration, logging, and remote diagnostics, essential for scaling quantum devices in the field.

Quantum-Powered Manufacturing Use Cases

SpinQ supports pilot collaborations where quantum algorithms improve factory scheduling, defect detection, and supply-chain optimization—bridging real-world manufacturing problems with quantum R&D.

Research and Training Partnerships

SpinQ works with universities and government programs (for example, initiatives launched under the U.S. National Quantum Initiative and Texas Quantum Initiative) to build quantum manufacturing capabilities and train industry-ready talent en.wikipedia.org.

Why Manufacturers Should Engage with SpinQ

| Value Area | SpinQ Advantage |

| Accessible Quantum Deployment | Deploy quantum systems without costly cryogenics or lab infrastructure |

| Pilot Innovation | Run experiments in optimization, logistics, materials, or predictive maintenance |

| Scalable Control Architecture | Firmware and electronics built for industrial upgrades and deployment |

| Domain Expertise Co‑Development | Cross-industry collaborations for applied quantum solutions |

| Workforce Development Support | Training programs to build quantum-aware professionals in manufacturing |

SpinQ offers both the tools and the domain know-how to accelerate quantum adoption in manufacturing contexts.

Challenges & Forward Trajectory

While momentum is growing, several challenges remain:

-

Hardware Scaling: Consistent, high-yield production of quantum chips at industrial scale demands robust fabrication innovation and manufacturing process control.

-

Algorithm Maturity: Quantum optimization routines must integrate with real manufacturing constraints—such as batching rules, safety margins, and multi-stage workflows.

-

Integration Complexity: Embedding quantum-enhanced modules into enterprise IT and operational systems requires system-level architecture and hybrid control interfaces.

-

Talent Gaps: Workforce readiness will be critical. Manufacturing staff need knowledge in hybrid quantum-classical workflows and quantum-aware analytics.

SpinQ supports these challenges through modular system architecture, training programs, and ongoing research focused on coherence scaling, automation, and hybrid quantum-classical pipelines.

Final Thoughts

Quantum Manufacturing is driving a new phase in production—one where quantum hardware is mass-produced and quantum algorithms help shape industrial workflows from supply chain to factory floor.

SpinQ is uniquely positioned to accelerate this evolution. With accessible hardware, scalable control systems, quantum analytics, and prototype use cases, we help make the promise of quantum manufacturing practical today.

Explore pilot projects, deploy quantum hardware, and implement quantum optimization workflows with SpinQ, integrating quantum innovation into operational excellence.

SpinQ – Advancing Quantum Manufacturing, Powering Next-Gen Industry.

Featured Content