China's Quantum Manufacturing Leap: SPINQ's Innovations Explained

2025.06.25 · Blog quantum manufacturing

China's Quantum Manufacturing Leap: SPINQ's Innovations Explained

Uncover how China is revolutionizing quantum manufacturing, from chip design to industrial-scale production. Learn how SPINQ's breakthrough tools are shaping the future of quantum technology.

.jpg)

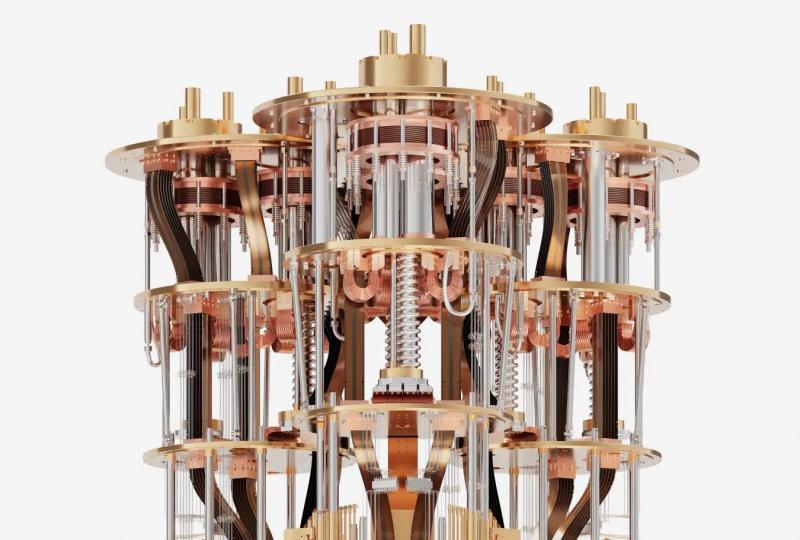

What Is Quantum Manufacturing?

Quantum manufacturing refers to the process of creating quantum computing hardware—like qubits and quantum processors—using advanced fabrication techniques. Unlike classical chip manufacturing, it requires precision at the atomic scale to harness quantum properties like superposition and entanglement. China has emerged as a leader in this field, with companies like SPINQ pioneering technologies that bridge research and mass production .

China's Quantum Manufacturing Ecosystem

China's rapid rise in quantum manufacturing stems from a blend of government investment, academic research, and corporate innovation. Key milestones include:

-

First Superconducting Chip Exports: SPINQ became the first Chinese company to export superconducting quantum chips globally, demonstrating manufacturing parity with international leaders .

-

Global Market Reach: Quantum products from China now sell in over 30 countries, with SPINQ's desktop quantum computers used in universities from Australia to Europe .

-

Full-Stack Capabilities: Companies like SPINQ control the entire manufacturing chain, from quantum chip EDA design software to cryogenic system integration .

SPINQ's Quantum Manufacturing Tools: A Closer Look

SPINQ QEDA: The Quantum Chip Design Powerhouse

SPINQ QEDA is a game-changing EDA (Electronic Design Automation) tool for quantum chips, featuring:

-

Parametric Design: Customize qubit components (length, width, position) with real-time simulation .

-

One-Click Layouts: Automatically generate optimized chip layouts from design parameters, cutting development time .

-

Drag-and-Drop Routing: Modify signal paths intuitively to resolve conflicts and enhance qubit coherence .

-

Web-Based Access: No downloads needed—design chips from anywhere via a browser, fostering global collaboration .

SPINQ's superconducting QPU production stands out for:

-

High-Fidelity Qubits: Single-qubit gate fidelity exceeding 99.9%, double-qubit fidelity at 99%—critical for error-free quantum operations .

-

Decoherence Control: QPUs maintain quantum states for up to 102 microseconds (T1), enabling complex algorithm execution .

-

Modular Scalability: QPUs with 2 to 20 qubits support 1D/2D topologies, adaptable for research or industrial applications .

-

Factory Testing: Every QPU ships with a detailed characterization report, ensuring manufacturing consistency .

Advantages of China's Quantum Manufacturing Approach

-

Speed & Efficiency: Automated tools like SPINQ QEDA reduce chip design cycles from months to weeks .

-

Cost-Effectiveness: In-house production lines and standardized processes lower quantum hardware costs.

-

Technical Rigor: Precision manufacturing achieves sub-nanosecond synchronization and 16-bit resolution in control systems .

-

Scalability: Modular designs allow easy expansion from research-grade 2-qubit chips to industrial 20-qubit systems .

Impact on Global Quantum Industry

China's manufacturing innovations are reshaping quantum technology:

-

Education Democratization: Portable NMR quantum computers (e.g., SPINQ Triangulum Mini) bring quantum experiments to high school classrooms worldwide .

-

Industrial Applications: Quantum - classical hybrid algorithms developed in China are already optimizing ATM networks for banks like Huaxia Bank .

-

Research Acceleration: Partnerships with BGI Research use quantum manufacturing to speed up genome assembly by 30% .

FAQ: Quantum Manufacturing Simplified

-

How is quantum manufacturing different from classical chip making?

Quantum manufacturing requires controlling quantum states, needing cryogenic environments (20mK) and nano-scale precision for qubit coherence .

-

Can quantum manufacturing solve real-world problems today?

Yes! SPINQ's chips are used in financial risk analysis, drug discovery simulations, and even ATM network optimization for major banks .

The Future of Quantum Manufacturing in China

With ongoing investments in R&D (over 50% of staff at SPINQ are researchers) and strategic partnerships, China is poised to:

-

Develop fully automated quantum foundry services for global clients

-

Pioneer hybrid quantum - classical manufacturing workflows for industries like AI and materials science

As quantum manufacturing matures, China's blend of technical innovation and commercial pragmatism will likely define the next decade of quantum computing breakthroughs.

Featured Content